(2000) ANSI Class Wafer

- Description

- Product Specs

- Seat Options

Description

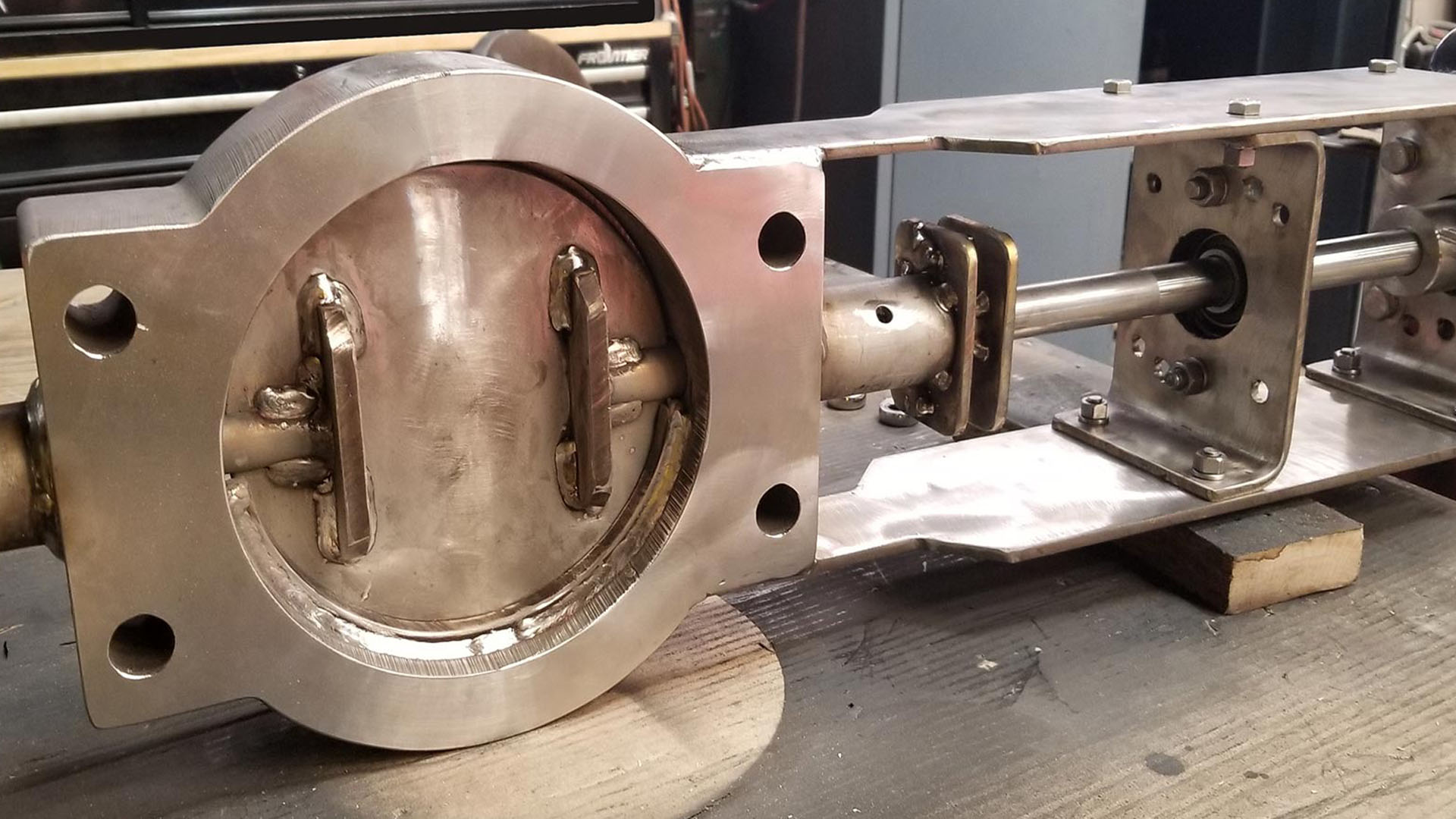

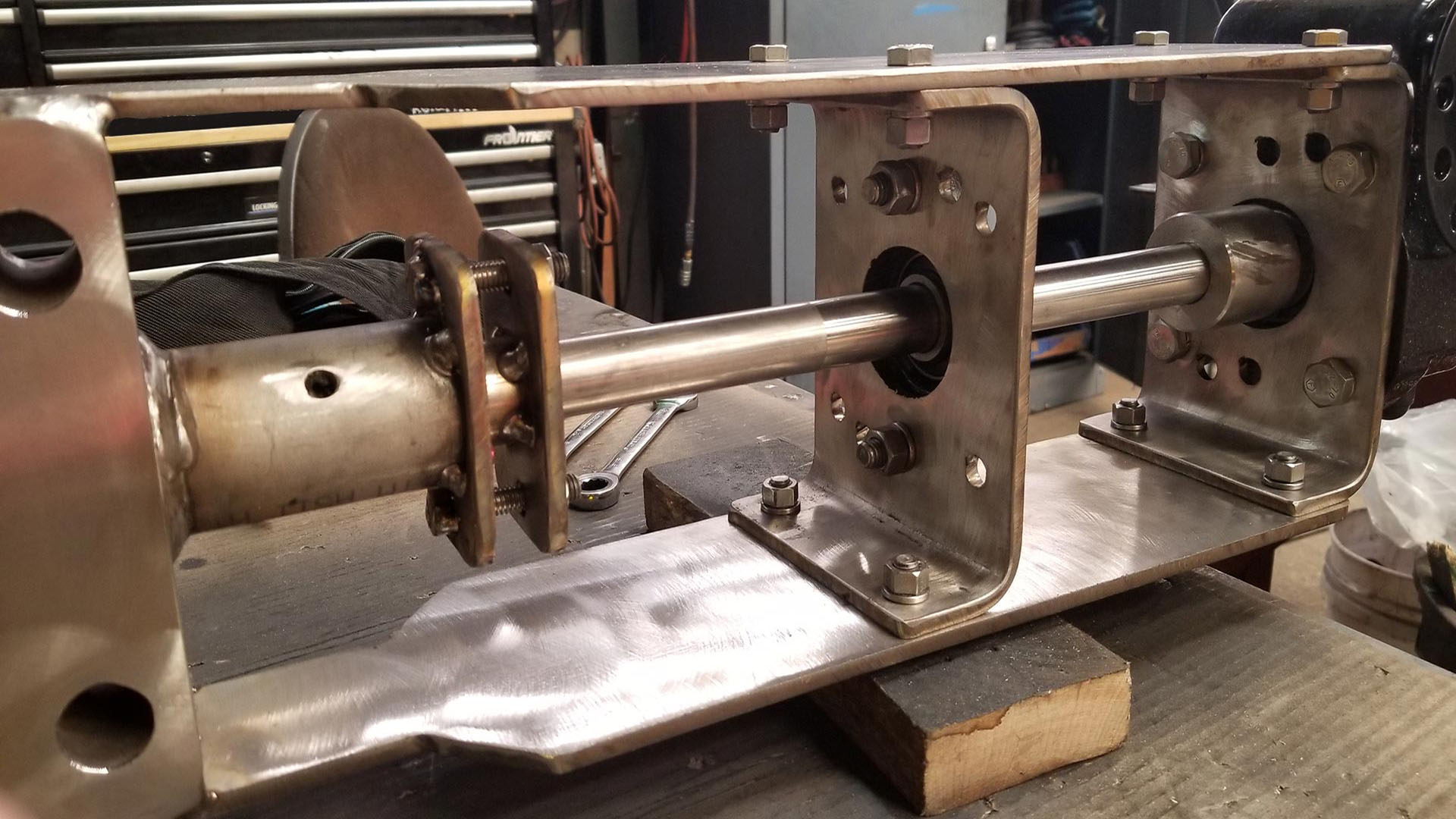

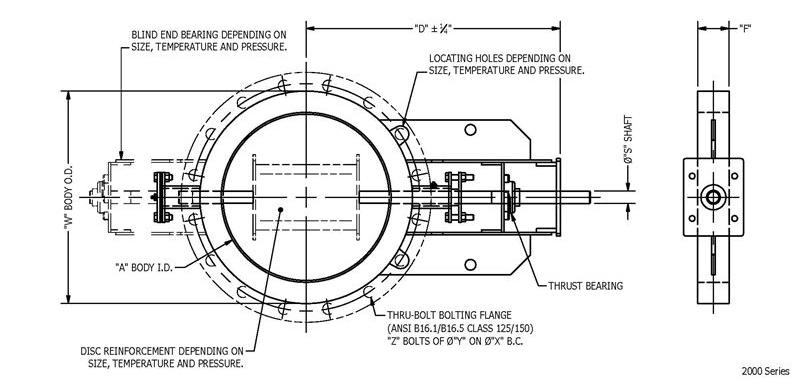

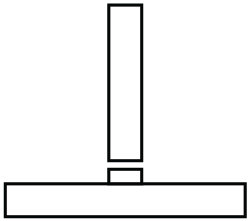

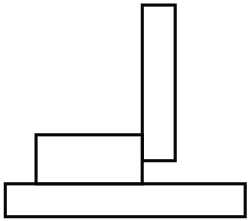

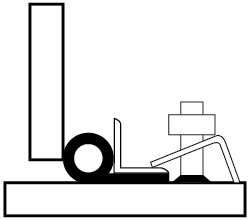

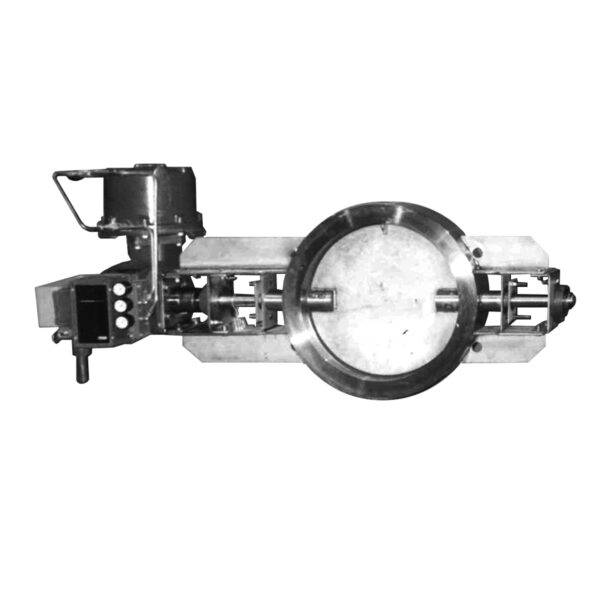

The 2000 series butterfly flange less control valve can be used in either throttling or on/off of varies applications. The valve body is constructed of carbon steel, stainless steel or special alloy with fabricated brackets and stuffing boxes welded to the body. The valve is constructed to bolt between two adjacent flanges on the duct/pipe. The standard valve design is to bolt between ANSI/ASME B16.1 Class 125 flanges. Sizes Ø24” and smaller also match ANSI/ASME B16.5 Class 150. For additional bolting standards and class ratings, give us a call. The valve’s flange face are flat face, machined or serrated. The 2000 series control valve can be supplied in all weldable materials.

- Sizes up to Ø66″ (Larger and special sizes consult for quote)

- Design is to bolt between 125/150# flanges.

- Blind end bearing is available as an option.

- Standard shaft is stub type. Through shaft is available as an option.

- Maximum pressure drop rating is at ambient temperature and 0°.

- All seat types may not be available for all sizes. Extended face-to-face may be required for some seats.

Ø8″ 2070-6 Damper Example

Industry Usage

2000 Series News

| Conventional | Scissor Seat | Metal Seat | Tadpole Seat |

|---|---|---|---|

| Swing-thru design, *4-5% leakage | Swing-thru design, approx. *1-2% leakage | Materials same as body - approx. *1% leakage | Material furnished varies with service. Temp. to 2,300˚F, approx. *1/4 of 1% leakage |

|  |  |  |

*Leakage based on damper capacity

2000 Series Round Butterfly Damper Specs

2000 Series Round Butterfly Damper Specs