Elite offers various services & capabilities providing high quality products!

Since taking over the Shan-Rod brand on May 1st, 2019 Elite Industrial Controls has been improving manufacturing processes, reducing overall production costs, investing in machinery and tooling to provide new techniques in fabrication and increases the amount of employees to achieve customer requested deadlines. At Elite we never stop innovating. It’s our nature to continuously improve and evolve to be the best we can possibly be as a company and individuals. We have implemented weekly product reviews, invested in research & development and receptacle to valuable customer criticism allowing for new product lines.

Laser Cutting

We are proud to announce that we can offer laser cutting services for our valve manufacturing with precision tolerances and offer manufacturing of outside customer parts for mass production. Our Trumpf laser has the capabilities to allow any designed part to be cut up to 3/4″ (20MM) thick steel, 1/2″ (15MM) thick stainless and 3/8″ (10MM) thick aluminum. The material ranges from standard steel, various grades/series of stainless steel and other exotic material.

Plasma Cutting

Our plasma cutting table allows larger size parts and thicker material to be cut with a more relaxed tolerances within reason. We have the ability to cut up to 1-1/4″ thick parts across various material types (carbon steel, stainless steel, etc). Cutting parts for larger assemblies becomes more cost efficient and is passed onto the customer with the best competitive quote.

Press Break Forming

With the friendly user interface and the ability to save and load bend programs on the fly allows new or existing part(s) to be formed within minutes. Our newer press brake can support up to 1/4″ (6MM) thick material ranging from standard carbon steel, stainless steel and aluminum. We can offer forming on thicker material and invest in additional tooling for reoccurring business.

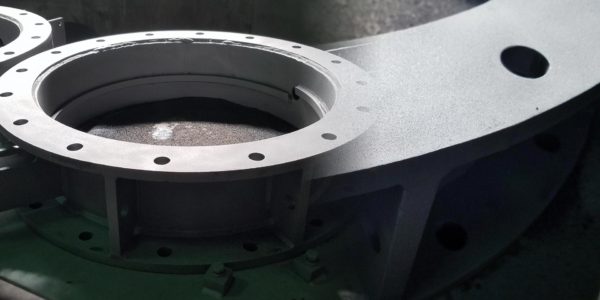

CNC & Custom Machining

Our in-house machine shop contains various drill presses, vertical milling machine, horizontal milling machine, several lathes, horizontal boring machine and a unique vertical lathe with turning capabilities of up to Ø60″ valves for custom machine facing. We have a large collection of tooling from imperial to metric covering 90% of standard sizing needed.

Welding & General Fabrication

Our welding department has over 30+ years of combined experience welding various materials and custom fabrication. Each welder is certified to ASME Section IX before anyone starts working on any product. This spec is for construction of boiler & pressure vessels which is held to a higher standard of approval to ensure a clean weld and integrity.

Sandblasting

Elite offers not only various valve manufacturing but also additional services including abrasive blasting/sandblasting done in-house. The sandblasting finish allows for Carbon Steel valves to be smooth allowing for a clean surface for the paint and/or epoxy to attach cleanly. Or if you have custom parts that are either customer provided or made in house we can offer a sandblast finish. Our facility is setup with a designated enclosed ventilated area to perform sandblasting upward to valve sizes of Ø96″ in diameter.

Powder Coating

We have partnered with a local powder coating company to save on the cost of valves and customer parts in bulk. With the partnership we can provide an all-in-one solution for our customers with precision laser cut parts, forming & additional machining of parts, welding assemblies of various complexity, powder coat finish of select color and bulk final assembly with various available testing for the customer to have on record of each product they have in the field.